Globe Valve vs Gate Valve

Globe valves and gate valves operate differently and serve distinct purposes. Globe valves feature a round body with a disc that moves vertically to regulate flow, making them ideal for precise flow control and effective sealing. In contrast, gate valves use a flat gate that lifts to allow flow or lowers to block it, providing a straight-through path with minimal resistance. Use globe valves when accurate flow regulation is needed, and gate valves for straightforward on/off control with minimal pressure loss.

Globe Valve vs. Gate Valve Comparison

Both globe valves and ansi gate valves are multi-turn, linear motion valves, meaning they require multiple rotations to fully open or close. In both types, the closing element moves up and down in a straight line to control flow. However, beyond this similarity, their differences become more pronounced.

The globe valve is named for its rounded body shape rather than its disc, unlike gate valves which are named after their flat gate component. The globe valve’s disc moves vertically to either allow or block flow, functioning somewhat like a gate. For a deeper understanding, consider exploring detailed resources on both globe and gate valves.

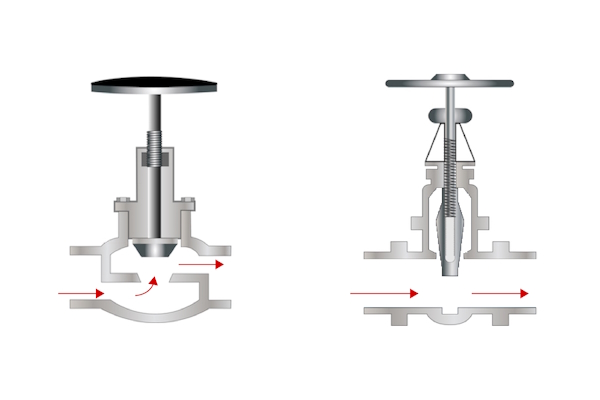

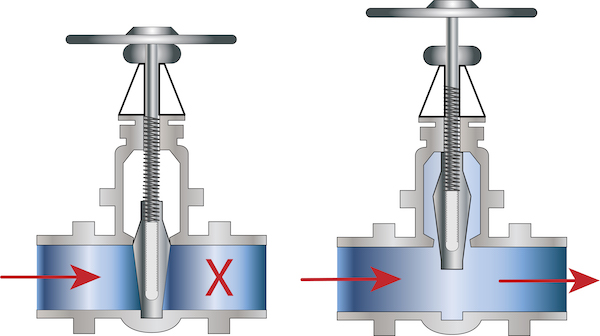

Flow properties

As seen in Figure 3, a gate valve is a straight-through, bi-directional valve, meaning its design permits flow directly through it in both directions. The only change to the flow occurs when the gate valve is closed, and the flow stops.

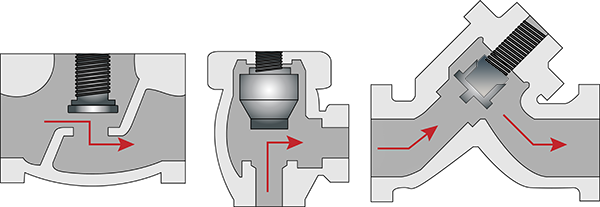

A globe valve, on the other hand, has more turns for the flow path. As seen in Figure 4, the flow can take a z-shaped path (T- or Z-valve), an oblique path (Y-valve), or a 90° turn path (angle valve).

Because a globe valve diverts flow in a specific way, it has an inlet and an outlet port. Typically, an arrow on the outside of the valve's body will indicate the valve's flow direction. Also, the flow diversion causes a significant pressure drop through the globe valve. In contrast, a gate valve's pressure drop is nearly non-existent.

Valve Functions

Both gate valves and globe valves can serve as on/off valves. However, gate valves are not designed for throttling flow, whereas globe valves are. In a globe valve, the flow is diverted and passes parallel to the valve seat, making it highly effective for flow regulation. That said, globe valves are generally not suitable for throttling in larger sizes (above DN 150). Both gate and globe valves can be actuated mechanically, pneumatically, or electrically.

Note: With other factors equal, Y-valves are the least efficient at throttling flow because the valve seat is not parallel to the flow direction. However, this also means that Y-valves have the smallest pressure drop.

Visual differences

At a quick glance, gate valves and globe valves are not easy to tell apart. The following traits are what to look for to tell the difference:

Body: Gate valves usually have a rectangular or wedge-shaped body. Whereas the body of a globe valve is rounder, especially at its bottom.

Maximum height: Gate valves are usually higher when opened than globe valves.

Flow direction indicator: Gate valves are bi-directional, whereas globe valves are unidirectional. A marker on the valve, such as an arrow, indicates the flow direction and that it's a globe valve.

Advantages and Disadvantages Chart

Globe and gate valves can be made from similar or different materials for their bodies and seals. To understand how these materials perform in various chemical environments, refer to our chemical resistance guide. Below is a chart summarizing the key advantages and disadvantages of globe and gate valves.

| Globe valve | Gate valve | |

| Application | Used for flow regulation (e.g., cooling water systems and fuel oil systems) | More suitable for slurry due to less space in the valve's body for sediment to get stuck and build up |

| Flow control | Can be used or on/off control and can throttle flow | Can be used for on/off control and cannot regulate the flow |

| Flow capacity | Lower | Higher |

| Flow direction | Unidirectional | Bi-directional |

| Flow restriction/pressure drop | Flow diversion within the valve's body creates significant pressure drop | Full-bore valve, meaning there is no reduction to flow and pressure drop is insignificant |

| Power requirement | Needs a large amount of force or an actuator to close under high pressure | Needs less power to close under high pressure |

| Operating conditions | Can operate at higher temperatures | Can operate at higher pressures |

| Cost | More expensive than a gate valve due to its complicated structure | Cheaper |

| Leakage | More effective sealing because force is applied to the disc when closed | Good sealing properties |

| Installation space | Takes up less vertical space, but requires more horizontal space | If a rising-stem style, needs more vertical space, but less horizontal space |

| Weight | Heavier | Lighter |

| Ports | Can have a 3-port configuration for straight-through flow | Two ports |

Selecting Between Globe Valves and Gate Valves

Both gate valves and globe valves serve effectively as shut-off valves. However, neither is universally superior—choosing the right valve depends on specific application needs. Consider the following factors when making your selection:

Flow Control: Choose a globe valve when precise flow modulation is required.

Flow Capacity: Opt for a gate valve if high flow capacity is needed.

Flow Direction: Select a gate valve for applications requiring bi-directional flow.

Pressure Drop: Use a gate valve when minimal pressure drop is important.

Sealing: For applications demanding excellent sealing, a globe valve is preferable.

Contaminated Media: Gate valves are better suited for slurry or other contaminated media due to their design.

Example Applications

Globe Valves:

Cooling Water Systems: Globe valves regulate water flow to maintain desired temperatures in cooling systems.

Chemical Injection Systems: Ideal for precise control of chemical flow into reaction vessels or process streams in industrial settings.

Gate Valves:

Bulk Material Handling Systems: Used in heavy-duty industries like mining, agriculture, and construction to control flow of bulk materials such as grains, coal, and aggregates.

Water Distribution Systems: Suitable where precise flow control is not necessary, as gate valves provide simple on/off operation for flow regulation.

FAQs

Which is better: a gate valve or a globe valve?

Globe valves offer better sealing and generally have a longer lifespan. However, gate valves provide significantly lower pressure drop, making them more efficient for full-open flow.

What is the advantage of gate valves over globe valves?

Gate valves require much less power to close because their gate moves perpendicular to the flow, whereas globe valves close parallel to the flow, which demands more force.